Great piece of wood, decent quality, ideal for all sorts of laser projects.

Great quality, will order again.

Love the quality of the italian poplar.

Beautiful quality and grea comunication.

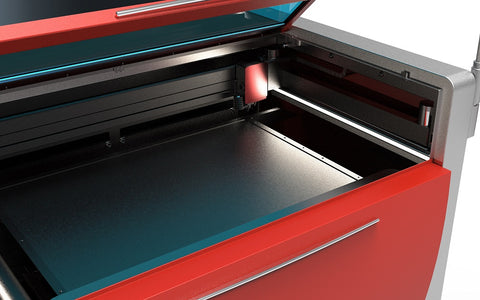

The ULTRA X6000 platform offers laser material processing for the widest possible range of materials. It is designed and ideally suited for precision material processing in manufacturing, research and development, academic research, and prototyping environments. With its unique modular architecture, customizable solutions can be easily reconfigured with a wide array of options for enhancing performance, capability, and safety to complete the perfect solution to meet present and future business needs.

The ULTRA X6000 platform has a materials processing envelope of 914 x 610 mm (36 x 24 in), with support for materials with a thickness up to 305 mm (12 in).

Configure the customizable ULTRA X6000 platform with up to three laser sources consisting of two interchangeable CO2 lasers and one fiber laser. When the platform is configured with three lasers, users can take full advantage of MultiWave Hybrid™ technology enabling up to three wavelengths – 9.3 µm, 10.6 µm, and 1.06 µm – to be simultaneously combined into a single coaxial beam. Each spectral component of the beam is independently controlled and can be modulated in real time.

Major features include multiple laser support, rapid high-accuracy laser beam positioning, precision material-independent autofocus, controllable laser power density, an automation interface, camera registration, an integrated touch screen control panel and over temperature detection.

System Specifications

Laser Sources Available

Laser Sources Combinations

Maximum Laser Power

CO2: 300 watts

[150 watt CO2 laser available 2021]

Fiber: 50 watts

Weight 250 Kg

Power Requirements 220V-240V/20A

Computer Requirements

Minimum: Intel i3 processor (or equivalent) with at least 8 Gb of memory, Windows 10 operating system, and connection to laser system with USB cable.

(Computer is not required if configured with optional 21” Touch Screen Control Panel)

Laser Safety Classification

Class 1 for material processing lasers

Class 2 overall due to red laser pointer

Can convert to Class 4 with optional Class 4 module

Shipping and delivery will be included in any formal quotation for the laser and no additional fees are applicable.